Hebei wear-resistant pipe fittings manufacturers: wear-resistant pipe fittings material

Release time:

2024-03-21

Hebei wear-resistant pipe fittings manufacturers introduced that wear-resistant pipe fittings are pipe components with excellent wear resistance and are widely used in various scenes with serious wear, such as the transportation of mine filling materials, ore concentrate and tailings, and wear-resistant pipes such as powder feeding, slag removal and ash transportation in coal-fired thermal power plants. There are many types of wear-resistant fittings, and their material selection and application scenarios are different.

Hebei wear-resistant pipe fittings manufacturersIt is introduced that wear-resistant pipe fittings are pipe components with excellent wear resistance, which are widely used in various scenes with serious wear, such as the transportation of mine filling materials, ore concentrate and tailings, and wear-resistant pipes such as powder feeding, slag removal and ash transportation in coal-fired power plants. There are many types of wear-resistant fittings, and their material selection and application scenarios are different.

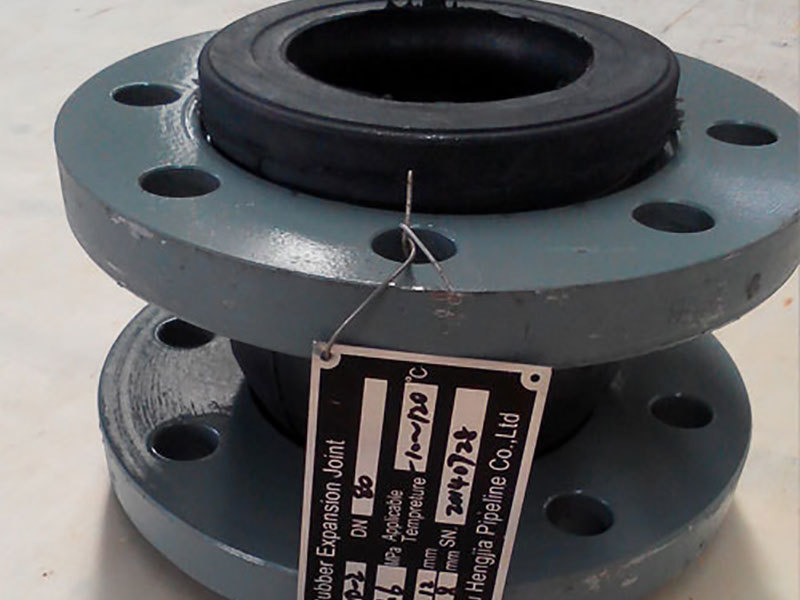

First of all, the material of wear-resistant pipe fittings can be basically divided into four categories: polymer material pipe, inorganic non-metallic material pipe, metal material pipe and composite material pipe. Among them, the bimetal wear-resistant pipe in the metal material pipe is a common wear-resistant pipe, the inner layer is wear-resistant alloy steel pipe, and the outer layer is ordinary carbon steel pipe. This structure enables the pipe to maintain wear-resistant performance while reducing manufacturing costs. In addition, ceramic wear-resistant pipe, polyurethane wear-resistant pipe and stainless steel wear-resistant pipe are also common types of wear-resistant pipe fittings.

Hebei wear-resistant pipe fittings manufacturers said,The ceramic wear-resistant pipe uses ceramic material as the lining, and the wear resistance is more than 20 times that of ordinary steel pipe, which is especially suitable for conveying high wear media. Polyurethane wear-resistant pipe is made of polyurethane material as the lining, wear resistance is more than 5 times the ordinary rubber tube, suitable for conveying a certain degree of wear media. The stainless steel wear-resistant pipe is mainly made of stainless steel, which has good corrosion resistance and wear resistance.

In the design and manufacturing process of these wear-resistant pipe fittings, various factors will be taken into account, such as the thickness of the wear-resistant layer, hardness, impact performance, temperature resistance, etc., to meet the requirements of different working conditions. At the same time, the outer layer of wear-resistant pipe fittings is usually derusted and painted to improve its corrosion resistance and aesthetics.

In general, wear-resistant pipe fittings are the key components to ensure the long-term stable operation of the pipeline system, and their selection and use need to be carried out according to specific application scenarios and needs.

Key words:

Hengjia Pipeline

Valve

Related News