Flat flanges vs. brushed flanges: Which is better for your project?

Release time:

2024-02-18

Flat flange manufacturer is a company specializing in providing flat flange products and solutions. They have rich experience and professional team, and can customize high-quality flat flange products according to customers' needs. If you are looking for a flat flange manufacturer, you may wish to consider contacting them for more information and to choose the best flat flange connection method for your project.

Flat flanges vs. brushed flanges: Which is better for your project?

In the project, choosing the correct flange connection is very important for the success of the project. In the choice of flange connection, flat flange and drawing flange are two common options. So, what is the difference between flat flanges and brushed flanges? Which is more suitable for your project? Let's take a look.

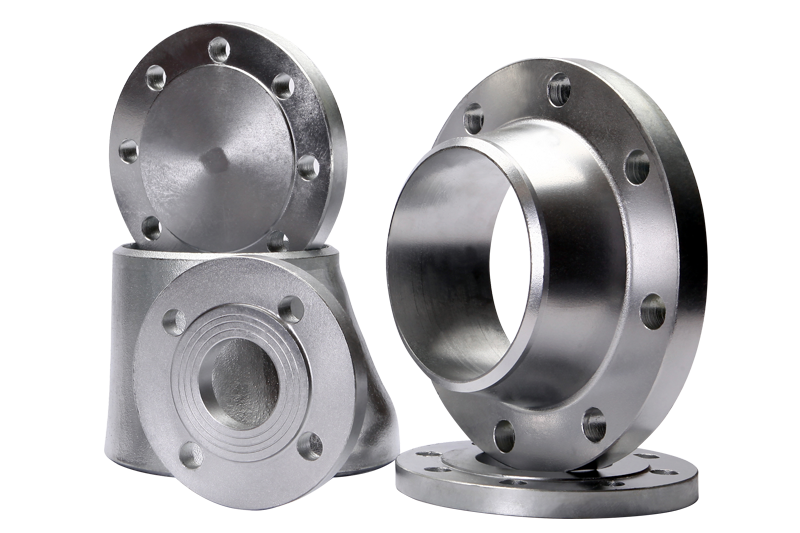

First, let us understand the flat flange. Flat flange is a kind of flange connection with flat connection surface. It is usually made of carbon steel, stainless steel or alloy steel, with high strength and rigidity. The flat flange connects the two flanges together by bolts and nuts to form a reliable seal. The advantage of the flat flange is that it is simple to connect and easy to install and remove. In addition, the flat flange has high load-bearing capacity and compression resistance, and is suitable for high-pressure and high-temperature engineering projects.

In contrast, a drawing flange is a type of flange connection with a stretched connection surface. It is usually made of cast iron, carbon steel or stainless steel, and has a certain strength and toughness. The drawing flange connects the two flanges together by bolts and nuts to form a tight seal. The advantage of the drawing flange is that it is firmly connected and can withstand large tension and shear forces. In addition, the drawing flange has good shock resistance and wear resistance, and is suitable for projects that need to resist external shock and vibration.

So, how to choose the right flange connection for your project? It depends on the specific needs and requirements of your project. If your project requires high strength and rigidity, and needs to withstand high pressure and high temperature, then flat flange may be a better choice. The flat flange can provide reliable connection and sealing, ensuring the safety and stability of the project.

On the contrary, if your project needs to withstand high tension and shear forces, and needs to resist external shock and vibration, then brushed flanges may be more suitable for your project. The drawing flange can provide strong connection and tight seal, ensuring the reliability and durability of the project.

In summary, flat flange and drawing flange have their own advantages and scope of application. Choosing the right flange connection for your project needs to consider the specific needs and requirements of the project. Before making a decision, it is recommended that you inquire with a professional flat flange manufacturer or brushed flange manufacturer to learn more about flange connection methods to ensure that your project chooses the correct connection method.

In the project, choosing the correct flange connection is very important for the success of the project. In the choice of flange connection, flat flange and drawing flange are two common options. So, what is the difference between flat flanges and brushed flanges? Which is more suitable for your project? Let's take a look.

First, let us understand the flat flange. Flat flange is a kind of flange connection with flat connection surface. It is usually made of carbon steel, stainless steel or alloy steel, with high strength and rigidity. The flat flange connects the two flanges together by bolts and nuts to form a reliable seal. The advantage of the flat flange is that it is simple to connect and easy to install and remove. In addition, the flat flange has high load-bearing capacity and compression resistance, and is suitable for high-pressure and high-temperature engineering projects.

In contrast, a drawing flange is a type of flange connection with a stretched connection surface. It is usually made of cast iron, carbon steel or stainless steel, and has a certain strength and toughness. The drawing flange connects the two flanges together by bolts and nuts to form a tight seal. The advantage of the drawing flange is that it is firmly connected and can withstand large tension and shear forces. In addition, the drawing flange has good shock resistance and wear resistance, and is suitable for projects that need to resist external shock and vibration.

So, how to choose the right flange connection for your project? It depends on the specific needs and requirements of your project. If your project requires high strength and rigidity, and needs to withstand high pressure and high temperature, then flat flange may be a better choice. The flat flange can provide reliable connection and sealing, ensuring the safety and stability of the project.

On the contrary, if your project needs to withstand high tension and shear forces, and needs to resist external shock and vibration, then brushed flanges may be more suitable for your project. The drawing flange can provide strong connection and tight seal, ensuring the reliability and durability of the project.

In summary, flat flange and drawing flange have their own advantages and scope of application. Choosing the right flange connection for your project needs to consider the specific needs and requirements of the project. Before making a decision, it is recommended that you inquire with a professional flat flange manufacturer or brushed flange manufacturer to learn more about flange connection methods to ensure that your project chooses the correct connection method.

Key words:

Hengjia Pipeline

Valve

Related News